Home > CCO wear plate

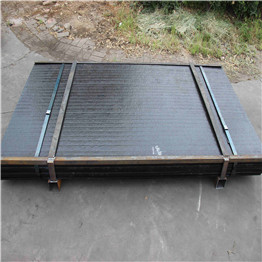

Impact Resistant Wear Plate

- Steel Grade:Impact Resistant Wear Plate

- Thickness:8+8

- Executive standard :Mill Standard

- Delivery Status:Mill standard

- Product descriptionпјљWear resistance:Our test shows that the wear resistance plate is 20 times higher than low carbon steel and 8 times than heat treated steel.Independent R&D, with high wear and high impact resistance;

Features & Benefits

Cost effective solution when compared to traditional abrasion-resistant steelsChromium Carbid layers web

Recommended for resistance to wear by abrasion, fretting, cavitation, and particle erosion in high temperature applications (up to 1100В°F).

- Ideal for mild to moderate impact abrasion resistance.

- Low maintenance cost and easy installation.

- The overlay surface of CCO plate will consist of a series of beads with numerous

- hairline cracks in them. These properly spaced crosscheck cracks are a natural

- phenomenon and are beneficial to the material. The cracks propagate through the overlay and end at the fusion line.

- Cutting – Plasma burning, air arc, abrasive saw or water jet.

- Welding – Our CCO overlay plate can be joined by welding the substrate to substrate using 309 weld wire/rod.

- Bending – Using a press brake, forming should be perpendicular to the weld pass direction.Plate rolling should be performed in the directions of the overlay beads.

- Hardness ranges from 58-62 HRC based on weld thickness

- Superior wear resistance

- Optimum solution for most industrial applications

PREVIOUSпјљHigh Chromium Wear Plate

NEXTпјљNo Crack Wear Plate

Categories

Contact

CONTACT USContact:sales

Phone: 0086-18539970286

Emailпјљzzgjsteel@foxmail.com

AddпјљNO. 2322, 23 / F , CAIZHI MINGZUO, NO. 3-3 DONGFENG ROAD, JINSHUI DISTRICT, ZHENGZHOU CITY, HENAN PROVINCE, CHINA

Ms He

Ms He Ms He

Ms He